We design, manufacture and assemble all kinds of special-purpose machinery. Our services include automation and full documentation. This is rounded off by on-site commissioning, training and service. Among other things, we offer special-purpose machinery in the fields of forming, welding, assembly and process engineering.

Here you will find examples of our competence:

Welding machine

Welding machineThis system is designed to weld metal bellows and their connecting parts by means of TIG welding. The welding torch is able to produce a wider weld seam by means of an oscillating movement.

The entire jig (center) can be swiveled up to 80° in both directions.

Welding positioner, semi-automatic

Welding positioner, semi-automaticThis welding machine is used for automatic circular welding of assemblies that have previously been tack-welded.

Welding technology: MAG

Slotter

SlotterThis device punches slots into pipe ends. Three slots are simultaneously punched into the workpiece at an angle of 120°. The three punching units are driven by jackscrew gears with servo motors.

Part diameter: 50 mm to 150 mm

Pipe wall thickness: 1 mm to 2.5 mm

Leak testing apparatus

Leak testing apparatusThis leak testing apparatus enables the testing of mufflers in the automotive industry. The DMC is scanned with a hand scanner and the corresponding program is loaded. After pressing the start button, the openings are closed, the muffler is loaded with test air and the leakage rate is evaluated. For OK parts, a printer prints a label which is attached to the muffler.

The muffler data is then stored in a database.

Measuring device

Measuring deviceThis system automatically measures various measuring points in exhaust systems from the automotive industry. The measurement is carried out by laser sensors.

All three axes X, Y and Z, are measured.

Welding, calibration and assembly machine

Welding, calibration and assembly machineThis production machine mounts an assembly out of 5 individual parts, then welds and calibrates it. Two nozzles are welded to a flange. The assembly is then joined with a corrugated pipe and calibrated. In addition, a connecting piece is pushed onto the other end of the corrugated pipe. Workpiece feeders and a NOK chute are mounted on and in the machine frame, respectively.

Forming, punching and embossing machine

Forming, punching and embossing machineThis machine is used by the automotive industry to reduce the diameter at the end of sheet metal jackets and to make several slits and multiple embossing. Calibration drive: hydraulic

Holding-down device: pneumatic

Embossing and punching units: hydraulic

Calibration machine for sheet metal jackets, hydraulic

Calibration machine for sheet metal jackets, hydraulicThis calibration machine is used by the automotive industry to reduce the diameter of sheet metal jackets and to emboss various shapes. 12 calibration jaws reduce the diameter of the sheet metal jackets. Inserts in the jaws form the embossing with an additional internal die. Calibration drive: hydraulic.

Exhaust filter assembly machine

Exhaust filter assembly machineThis system inserts parts of the exhaust filter into sheet metal housings.

All set-up parts are checked via RFID chips.

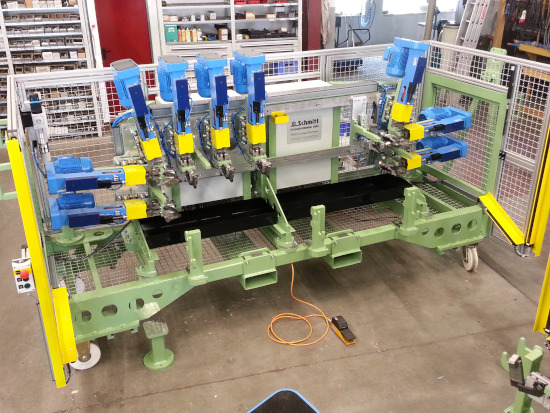

Drilling machine for bent pipes

Drilling machine for bent pipesThis drilling machine simultaneously drills 9 holes into a bent pipe.

Clamping: Pneumatic

drill drive: Electric

drill stroke: Pneumatic